Extrusion

Feature:

The aluminum extrusion process offers benefits other than weight savings. Components can be designed to incorporate extra features that provide fixings, channels, and interlocking systems that preclude the need for additional parts. These features can even be incorporated so that they enhance the structural strength of the assembly.

Materials:

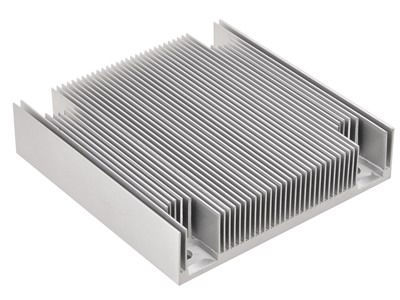

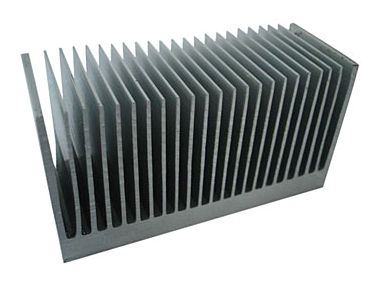

■ Aluminium is the most commonly extruded material. Aluminum can be hot or cold extruded. If it is hot extruded it is heated to 575 to 1100 °F (300 to 600 °C). Examples of products include profiles for tracks, frames, rails, mullions, and heat sinks.

■ Brass is used to extrude corrosion free rods, automobile parts, pipe fittings, engineering parts.

■ Copper (1100 to 1825 °F (600 to 1000 °C)) pipe, wire, rods, bars, tubes, and welding electrodes. Often more than 100 ksi (690 MPa) is required to extrude copper.

■ Lead and tin (maximum 575 °F (300 °C)) pipes, wire, tubes, and cable sheathing. Molten lead may also be used in place of billets on vertical extrusion presses.

■ Magnesium (575 to 1100 °F (300 to 600 °C)) aircraft parts and nuclear industry parts. Magnesium is about as extrudable as aluminum.

■ Zinc (400 to 650 °F (200 to 350 °C)) rods, bar, tubes, hardware components, fitting, and handrails.

■ Steel (1825 to 2375 °F (1000 to 1300 °C)) rods and tracks. Usually plain carbon steel is extruded, but alloy steel and stainless steel can also be extruded.

■ Titanium (1100 to 1825 °F (600 to 1000 °C)) aircraft components including seat tracks, engine rings, and other structural parts.

■ Plastic extrusion commonly uses plastic chips or pellets, which are usually dried in a hopper before going to the feed screw.

Products:

■ Plastic extrusion screw

■ Heat sink

■ Thermal module

■ Chassis

■ Casing

Extrusion Products Portfolio