Guide to Metal Fabrications: Tailored Process to Production

- Regulus Marketing

- May 17, 2024

- 2 min read

Updated: Mar 31

For people looking for metal fabrication solutions, it is often difficult to find the right manufacturing process. This week, Regulus will walk you through some of the most common processes we use to fabrication metal parts.

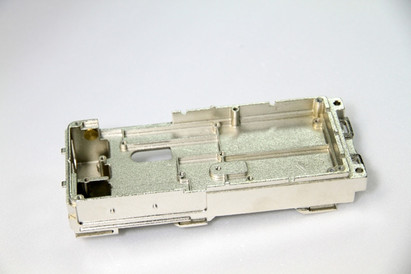

Regulus specializes in proving metal fabrication solutions for both trial run and mass production. To fabricate metal enclosures or casings, take a look at the following options:

Suitable for prototyping or low volume production. This process does not require a mold and can be used to shape various types of metals and plastics. It is also commonly applied in making customized threaded inserts.

Suitable for high volume production. This process is quite accurate and efficient thanks to the use of molds.

Suitable for high volume production. Can be made into special fin shapes commonly seen in heat sinks. Extruded parts possess many positive features of aluminum such as light-weight, good conductivity, and corrosion resistance.

To fabricate sheet metals, you should consider:

Suitable for prototyping or low volume production. Usually combined with other manufacturing processes such as bending and laser cutting to add details or create curves on the metal parts.

Suitable for high volume production. Compared with NCT punching, the automated stamping process is more precise, efficient and labor-saving.

It often takes a combination of several manufacturing processes to complete a product. If you want to add finer touches or upgrade how your product looks, you need plating and coating solutions.

If we are talking about an electronic device, you'll also need PCBA & box-build solutions. If lighter weight of a product is what you are aiming for, you might be considering using plastic instead of metal. Fortunately, Regulus has it all. Check out all the solutions we have!

Comments